Basic Principles of Anaesthesia Machine

Basic Principles of Anaesthesia Machine

Anaesthesia Machine

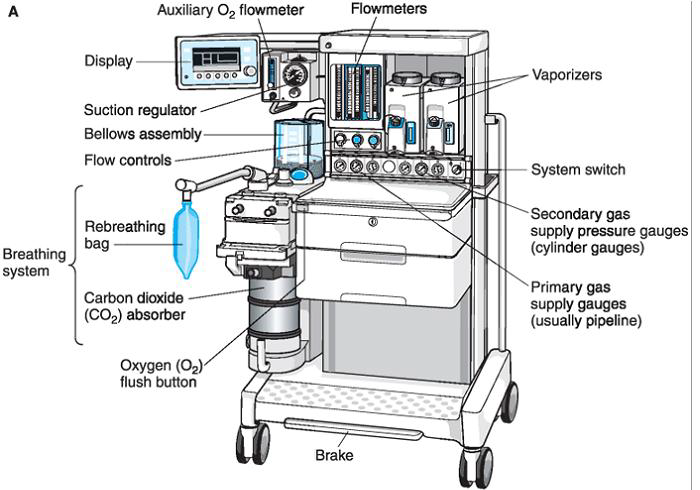

In its most basic form, the anaesthesia machine receives medical gases from a gas supply; controls the flow of desired gases reducing their pressure, when necessary, to a safe level; vaporizes volatile anaesthetics into the final gas mixture; and delivers the gases to a breathing circuit that is connected to the patient's airway (Figure 2.1 and Figure 2.2). A mechanical ventilator attaches to the breathing circuit but can be excluded with a switch during spontaneous or manual (bag) ventilation. An auxiliary oxygen supply and suction regulator are also usually built into the workstation.

Common Features of Anaesthesia Machine

- Inlet of hospital pipeline for compressed gases (oxygen, nitrous oxide, and air)

- Inlet of compressed gas cylinders

- Pressure regulators to reduce pipeline and cylinder pressure to safe and consistent levels

- Fail-safe device

- Flow meters to control the amount of gases delivered to the breathing limb

- Vaporizers for adding volatile anaesthetic gas to the carrier gas

- Common gas line through which compressed gases mixed with a volatile agent enter the breathing limb

- Breathing limb, including an oxygen analyzer, inspiratory one-way valve, circle system, gas sampling line, spirometer to measure the respiratory rate and volume, expiratory one-way valve, adjustable pressure-limiting valve, carbon dioxide absorbent, reservoir bag, mechanical ventilator, and scavenging system.

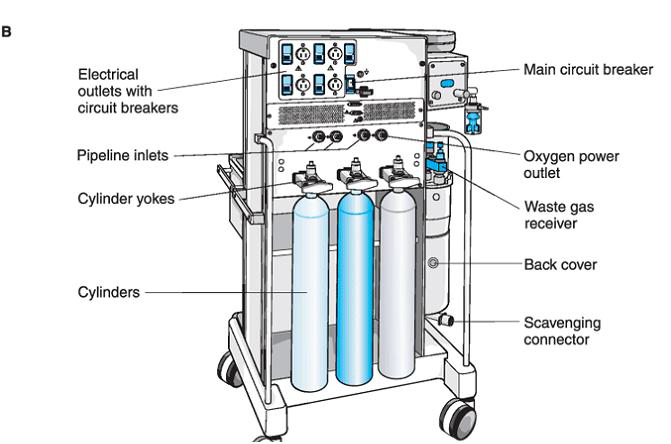

The oxygen cylinder in this image is E cylinder we can connect H cylinder by a flexible hose to the cylinder inlet

Inlet of Hospital Pipeline

Gas enters the anesthesia machine through the pipeline inlet connections. The pipeline inlet fittings are gas-specific Diameter Index Safety System (DISS) threaded body fittings. The DISS provides threaded non interchangeable connections for medical gas lines to minimize the risk of misconnection. A check valve located downstream from the inlet prevents reverse flow of gases from the machine to the pipeline or the atmosphere. (It has been explained in session one but in Ethiopia at this time most hospital does not implant the pipe line system)

Inlet of Compressed Gas Cylinder

Anesthesia machine have E cylinders for use when a pipeline supply source is not available or if the pipeline system fails. Medical gases (oxygen) supplied in E cylinders are attached to the anesthesia machine via the hanger yoke assembly. The hanger yoke assembly orients and supports the cylinder, provides a gas-tight seal, and ensures a unidirectional flow of gases into the machine. As it has been explained in session one each hanger yoke is equipped with the Pin Index Safety System (PISS) to safe guard cylinder interchanging and possibility of accidentally placing the incorrect gas.

However, pipe line system to deliver medical gases from central supply are not implanted yet in Ethiopia, gases used in anesthesia are usually supplied under high pressure in spun steel or aluminum cylinders of varying capacity. The most commonly used sizes are:

- H- Cylinder: freestanding, attached to the anesthesia machine by a flexible hose. These are most economical, but reduce the mobility of the anesthesia machine. The hose to the anesthetic machine should be at a regulated pressure of 50 psi (i.e the regulator should be attached to the cylinder and not to the anesthetic machine). This is very much safer than having the hose running from the cylinder to the machine at cylinder pressure (up to 2000 psi).

- E-Cylinder: attached directly to the anesthesia machine via a yoke. These allow the anesthesia machine to be more mobile, but are more expensive to operate.