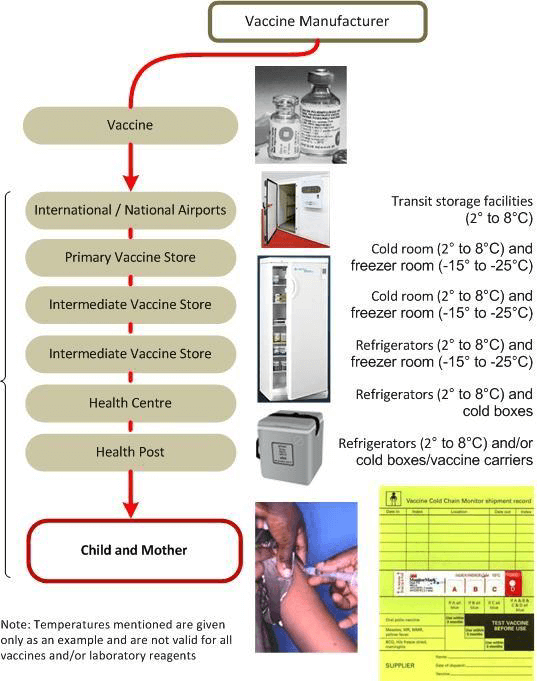

Components of the cold chain

The Cold Chain is a system of storing and transporting vaccines at recommended temperatures from the point of manufacture to the point of use. The key elements or components of the cold chain are the following:

- Personnel: to manage vaccine storage and distribution.

- Equipment: to store and transport vaccine and to monitor temperature.

- Procedures: to ensure that vaccines are stored and transported at appropriate temperatures.

Keeping vaccines at the right temperature is not an easy task, but the consequences of not doing so can be disastrous. Once vaccine potency is lost, it cannot be regained. The damaged vaccines must be destroyed, leading to inadequate vaccine stocks and wastage of expensive vaccines. Moreover, children and women who receive a vaccine that is not potent are not protected.Since vaccines are sensitive to heat and freezing, they must be kept at the correct temperature from the time they are manufactured until they are used.

The cold chain consists of a series of storage and transport links, all designed to keep vaccines within an acceptable range until it reaches the user (Figure 4.1 below). This requires vaccines and diluents to be:

- Collected from the manufacturer or an airport as soon as they are available.

- Transported between +2ºC and +8ºC from the airport and from one store to another.

- Stored at the correct temperature in primary/central and intermediate vaccine stores and in health facilities.

- Transported between +2ºC and +8ºC to outreach sites and during mobile sessions.

- Kept between +2ºC and +8ºC range during immunisation sessions and

- Kept between +2ºC and +8ºC during the return to health facilities from outreach sites.